Ultimate Guide to Choosing the Best Robot Motors for Your Projects

In the rapidly evolving realm of robotics, selecting the right robot motors is critical to the success of any project. According to a recent market report by Allied Market Research, the global robotics market is expected to reach $164 billion by 2026, with advanced motion control solutions driving much of this growth. As industries increasingly adopt automation to improve efficiency, understanding the nuances of robot motors becomes essential. These components not only dictate the performance and responsiveness of robotic systems but also play a pivotal role in application-specific scenarios such as manufacturing, agriculture, and healthcare. This ultimate guide will delve into various motor types, their industry applications, and the crucial factors to consider, ensuring you make informed choices that enhance your projects and meet the demands of this burgeoning market.

Understanding Different Types of Robot Motors: A Comprehensive Overview

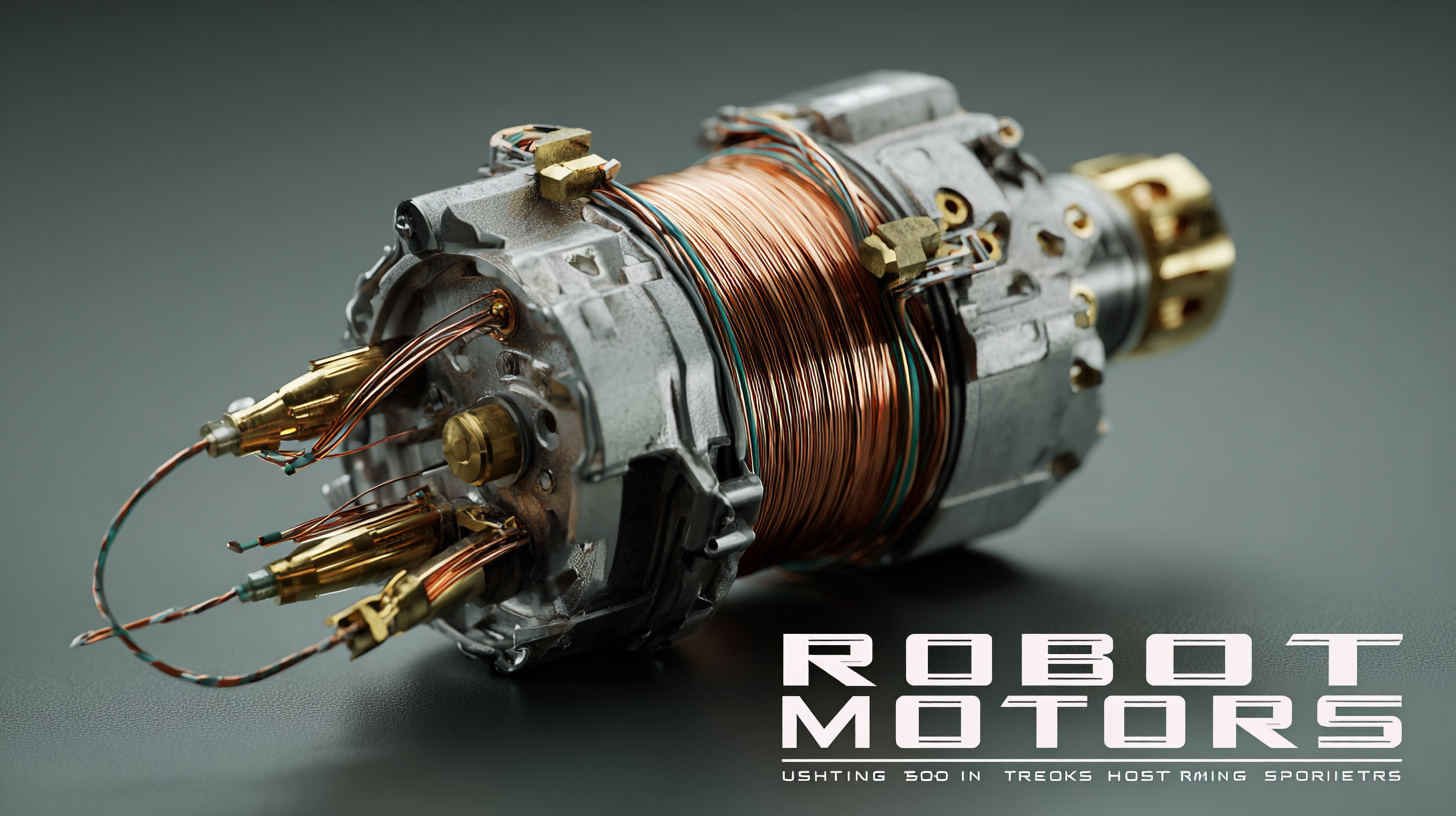

When embarking on a robotics project, selecting the right motor is paramount to ensure optimal performance. There are various types of robot motors, each suited for specific applications. DC motors are popular for their simplicity and cost-effectiveness. They offer smooth and continuous rotation but require additional components like encoders for precise control. Servo motors, on the other hand, provide excellent positional accuracy and are ideal for projects requiring limited angular motion—making them perfect for robotic arms and steering mechanisms.

When embarking on a robotics project, selecting the right motor is paramount to ensure optimal performance. There are various types of robot motors, each suited for specific applications. DC motors are popular for their simplicity and cost-effectiveness. They offer smooth and continuous rotation but require additional components like encoders for precise control. Servo motors, on the other hand, provide excellent positional accuracy and are ideal for projects requiring limited angular motion—making them perfect for robotic arms and steering mechanisms.

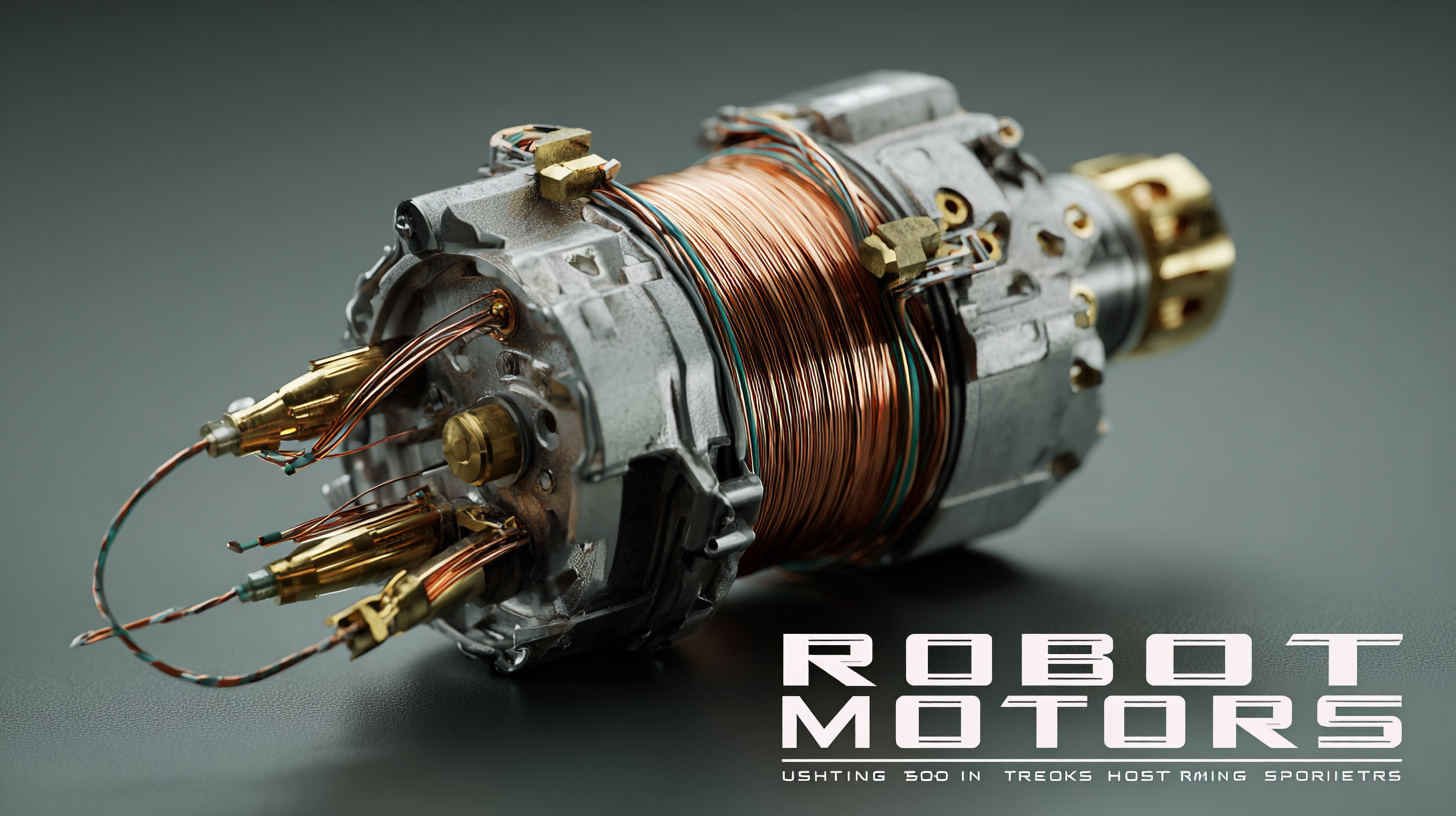

Stepping into more advanced territory, stepper motors enable precise control over rotation with a defined number of steps. This makes them particularly useful for applications that need specific positioning, such as 3D printers or CNC machines. Lastly, brushless motors provide high efficiency and longevity, though they often come at a higher price point and require more intricate control systems. Understanding these different types of motors can help you determine the best fit for your project’s needs, enhancing both functionality and efficiency.

Key Specifications to Consider When Selecting Robot Motors for Your Project

When selecting robot motors for your projects, understanding the key specifications is crucial to achieving optimal performance. Key factors include torque, speed, and power requirements, which directly influence the efficiency and capabilities of your robotic system. For instance, in a hexapod robot design, where both legs and wheels are utilized, servomotors must provide sufficient torque to support the weight and movement of the robot while maintaining balance. The ability to convert electrical energy into mechanical movement is essential for executing tasks that require precision, which is often governed by the specifications of the actuators used.

Furthermore, as robotics expands into various applications, safety and collaboration become fundamental aspects of selection. Motors used in industrial automation require careful consideration of their operational environment and compatibility with other systems. Studies suggest that robust actuator specifications can significantly enhance the collaborative performance of humanoid robots, allowing for smooth and human-like movements. The integration of motors that meet exacting standards can reduce the risk of system failures, making the robotics process more efficient and safe. Choosing the right motor isn't just about functionality; it's about ensuring that all components work harmoniously together in a well-designed robotic ecosystem.

Ultimate Guide to Choosing the Best Robot Motors for Your Projects

| Motor Type |

Voltage (V) |

RPM (Revolutions Per Minute) |

Torque (Nm) |

Current (A) |

Weight (kg) |

Control Type |

| DC Motor |

12 |

3000 |

0.5 |

1.0 |

0.15 |

PWM |

| Stepper Motor |

5 |

200 |

0.3 |

1.5 |

0.2 |

Digital |

| Servo Motor |

6 |

180 |

0.2 |

0.5 |

0.1 |

PWM |

| Brushless Motor |

24 |

4000 |

0.8 |

2.0 |

0.3 |

BLDC Controller |

Evaluating Motor Performance: Torque, Speed, and Efficiency Explained

When selecting robot motors, understanding motor performance is crucial for achieving optimal results in your projects. Torque, speed, and efficiency are three factors that significantly influence performance. Torque, measured in Newton-meters (Nm), indicates a motor's ability to generate rotational force. According to industry reports, motors with a higher torque rating are essential for applications requiring heavy lifting or quick acceleration. For example, a motor with 1.5 Nm of torque can effectively power larger robots or those with varying load requirements.

Speed is another critical metric, typically expressed in revolutions per minute (RPM). The ideal speed depends on the application; higher RPMs are preferable in applications needing rapid movement, while lower speeds might be suitable for precision tasks. Data indicates that a motor operating at 300 RPM may suffice for slow-moving robots, but applications like drone propulsion may necessitate speeds exceeding 1500 RPM to ensure agility and responsiveness.

Efficiency is the final pillar of motor performance, often defined as the ratio of output power to input power. A motor operating efficiently not only conserves energy but also extends the system's lifespan. Recent studies reveal that motors with an efficiency rating of over 85% can optimize energy use, especially in battery-operated systems. Consequently, when choosing motors for your projects, consider these performance metrics to maximize your robot's capabilities and longevity.

Matching Motors to Your Project's Requirements: A Practical Approach

When selecting motors for your robotics projects, aligning them with your project's specific requirements is crucial for ensuring optimal performance and efficiency. Different projects may demand distinct motor characteristics—like torque, speed, and control precision. For instance, if your project involves rapid movements, prioritizing high-speed motors would be advisable. Conversely, tasks requiring substantial lifting capabilities will benefit from motors with higher torque ratings.

Practical approaches to motor selection often include prototyping with various motor types to observe their real-world performance in the context of your project. This hands-on experimentation parallels recent advancements in technology, such as the photorealistic environments created by artists for virtual simulations. Just as these artists meticulously match elements to create lifelike scenes, you must evaluate and test motors to ensure they contribute effectively to your robotic designs, thereby enhancing the overall functionality and reliability of your projects.

Common Pitfalls to Avoid in Choosing Robot Motors for DIY Projects

When embarking on DIY robotics projects, selecting the right motor is crucial, yet many enthusiasts fall into common pitfalls that can derail their endeavors. One significant mistake is not considering the weight and load requirements of the robot. A motor that operates well under light conditions may struggle or fail entirely under a heavier load, leading to performance issues or even damaging components. It's essential to evaluate the expected weight of your robot and choose a motor with adequate torque specifications to match.

Another frequent misstep is overlooking the power requirements and compatibility with other electronic components. Using motors that operate at different voltages or currents than your power supply or control systems can result in inefficient performance or complete failure of the motor. Always check the motor's specifications and ensure that your entire system is compatible to avoid frustrating setbacks. Additionally, familiarize yourself with the different types of motors available—dc, stepper, or servo—and understand their unique benefits and limitations to ensure you choose the best option for your specific project needs.

Ultimate Guide to Choosing the Best Robot Motors

This chart presents the efficiency and torque ratings of various common robot motor types. It helps to understand which motors are suitable for different DIY projects based on their characteristics.

When embarking on a robotics project, selecting the right motor is paramount to ensure optimal performance. There are various types of robot motors, each suited for specific applications.

When embarking on a robotics project, selecting the right motor is paramount to ensure optimal performance. There are various types of robot motors, each suited for specific applications.