2025 How to Master Robotic Arm Design for Beginners and Experts

In the ever-evolving field of robotics, mastering the art of Robotic Arm Design is crucial for both beginners and experts alike. As the renowned roboticist Dr. Emily Chen states, "The future of automation relies heavily on our ability to innovate and refine robotic systems, starting with the fundamental designs of our tools." This sentiment encapsulates the essence of our journey into the complex yet fascinating world of robotic arms, where creativity meets technical prowess.

Robotic arms serve as the backbone of various industries, from manufacturing to healthcare, making their design a pivotal aspect of robotics engineering. Whether one is just starting out or is a seasoned professional looking to enhance their skills, understanding the principles of Robotic Arm Design is key to unlocking new possibilities and improving efficiencies. This introduction aims to guide you through the foundational elements and advanced techniques required to become proficient in this domain, ensuring that every enthusiast can contribute to the future of robotics with confidence and expertise.

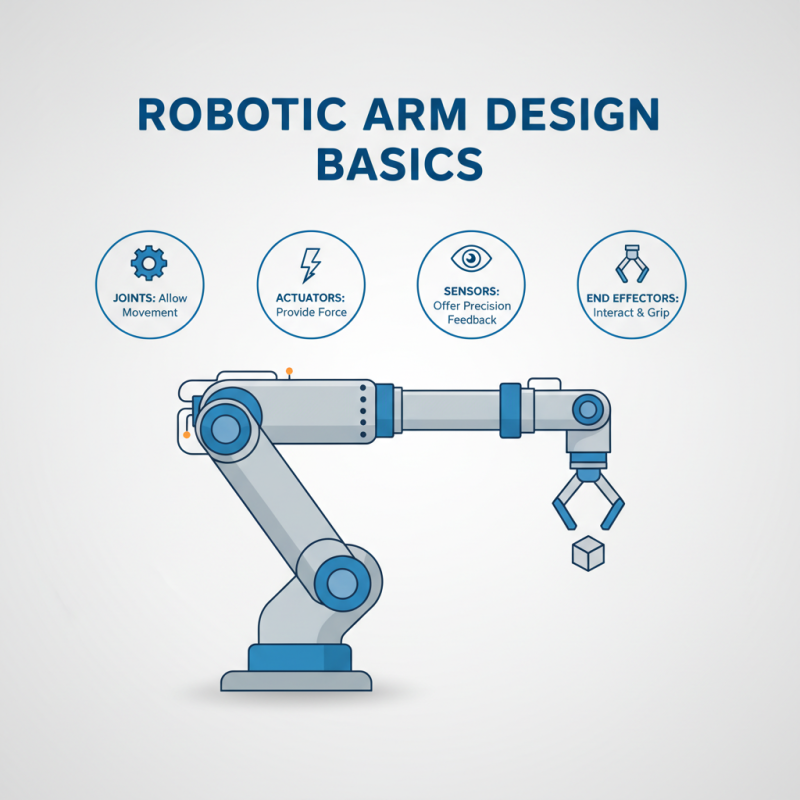

Basics of Robotic Arm Design: Key Concepts for Beginners

When embarking on the journey of robotic arm design, it's essential for beginners to grasp several key concepts that form the foundation of this intricate field. First, understanding the basic components of a robotic arm is crucial. These typically include joints, actuators, sensors, and end effectors, each playing a significant role in the functionality of the arm. Joints allow for movement, actuators provide the necessary force, sensors offer feedback for precision, and end effectors are the tools or grippers that interact with the environment. Familiarization with these components enables aspiring designers to visualize how the robotic arm will operate and interact with various tasks.

Another important aspect to consider is kinematics, which pertains to the motion of the robotic arm without regard to the forces involved. Knowledge of forward and inverse kinematics is essential, as it helps in planning the desired trajectory and positioning of the arm. Beginners should practice modeling simple movements to build confidence before tackling more complex tasks. Additionally, programming and control systems must be understood to effectively command the arm's movement. By mastering these basics, both novices and experts can refine their skills in robotic arm design, leading to innovative applications in numerous fields.

Essential Tools and Software for Designing Robotic Arms

When embarking on the journey of robotic arm design, having access to the right tools and software is crucial, regardless of your experience level. For beginners, user-friendly software such as simulation tools can help visualize designs and understand the fundamentals of robotic mechanics. These platforms often come with tutorials and pre-built models that allow novices to experiment without the steep learning curve often associated with advanced engineering software. Basic CAD (Computer-Aided Design) tools also prove indispensable, enabling users to create and manipulate designs in a virtual space, paving the way to practical prototyping.

For experts, the focus shifts toward more sophisticated software that supports complex simulations and kinematic analyses. Advanced engineering tools allow professionals to assess the performance of robotic arms under varying conditions, fine-tuning elements like torque, speed, and positional accuracy. These applications often integrate programming capabilities to develop responsive algorithms that govern arm movement, making it possible to test and implement real-time adjustments. Combining these advanced tools with knowledge from disciplines such as control theory and machine learning can lead to innovative designs that push the boundaries of traditional robotic functionality.

Robotic Arm Design Tools Usage by Skill Level

Step-by-Step Guide to Building Your First Robotic Arm Prototype

Building your first robotic arm prototype can be an exciting venture that merges creativity with engineering principles.

According to a report by Research and Markets, the robotic arm market is expected to grow at a CAGR of 12.4%, reaching $24.6 billion by 2025. This growth highlights the increasing relevance and accessibility of robotic technology across various industries, making it the perfect time for beginners and experts alike to dive into design and construction of robotic arms.

To embark on your journey, start by familiarizing yourself with the core components of robotic arms, which include servos, controllers, and sensors. There are numerous open-source platforms and software that cater to different skill levels, enabling you to simulate your designs before actual assembly. For example, programming environments like Arduino and Raspberry Pi are beginner-friendly and offer vast communities for support.

Integrating sensors for feedback can enhance precision, making your prototype not only functional but efficient. A comprehensive step-by-step approach will not only streamline your building process but also solidify your understanding of robotics fundamentals, setting a strong foundation for more advanced projects in the future.

Advanced Techniques in Robotic Arm Manipulation and Control

Robotic arm manipulation has evolved significantly, commanding attention in various fields such as manufacturing, healthcare, and research. According to a recent report by the International Federation of Robotics, the global market for robotic arms is projected to reach $37 billion by 2025, reflecting a compound annual growth rate (CAGR) of 14%. This surge is largely due to advancements in control algorithms, which enable more precise and versatile movements. For beginners and experts alike, mastering these techniques is crucial in harnessing the full potential of robotic arms.

Advanced control methods, such as Model Predictive Control (MPC) and reinforcement learning, are redefining how robotic arms can perform complex tasks. MPC allows for predictive modeling of the robotic arm's dynamics, optimizing performance in real time. Meanwhile, reinforcement learning enables robotic systems to learn from their experiences, iterating on their capabilities through trial and error.

A study published in the Journal of Robotics and Automation found that robotic arms utilizing these advanced techniques increased their operational efficiency by 30%, showcasing their transformative impact on automation processes. Engaging with these methodologies provides a pathway to not only improve productivity but also to innovate robotic arm applications across various sectors.

Integrating Sensors and Feedback Systems for Improved Functionality

Integrating sensors and feedback systems is crucial for enhancing the functionality of robotic arms, whether for beginners or experts in the field. The introduction of advanced sensor technologies has significantly improved the precision and responsiveness of robotic systems. According to a report by MarketsandMarkets, the global market for robotic sensors is expected to grow from $1.2 billion in 2020 to $3.7 billion by 2025, at a CAGR of 25.6%. This growth highlights the increasing importance of sensors in achieving better performance and adaptability in robotic applications.

Feedback systems, particularly in robotic arm design, allow for real-time monitoring and adjustments, facilitating more intuitive control mechanisms. For instance, the implementation of force and torque sensors can provide critical data that enables robotic arms to perform delicate tasks with accuracy and stability. A recent study by ABI Research indicated that incorporating feedback mechanisms can enhance the operational efficiency of robotic systems by up to 40%. This means that not only can robotic arms execute tasks more finely, but they can also adapt to varying external conditions, making them more versatile for a range of applications from manufacturing to medical surgery. As such, mastering these technologies is essential for anyone looking to excel in robotic arm design.