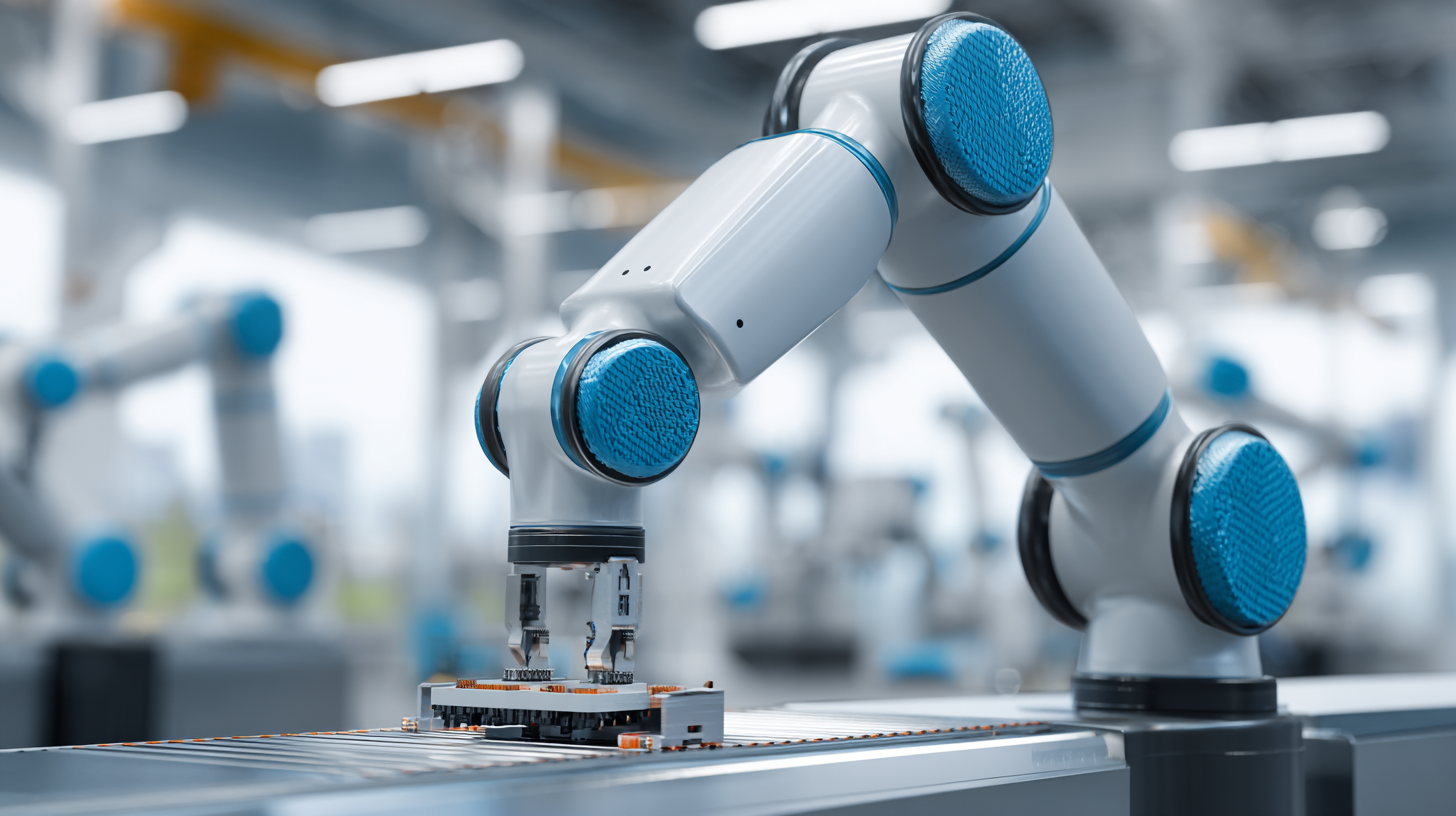

Digital Revolution Enhancing the Best Collaborative Robot Arm Experience

As industries increasingly embrace automation, the demand for Collaborative Robot Arms, or cobots, has grown significantly. According to a report by MarketsandMarkets, the global market for collaborative robots is expected to reach $12.3 billion by 2025, driven by their ability to work alongside humans safely and enhance productivity. This rapid evolution in robotics technology necessitates companies to seek high-quality suppliers that can offer reliable and cutting-edge solutions tailored to their specific needs. To navigate this complex landscape effectively, it is imperative to employ top strategies for selecting suppliers that specialize in Collaborative Robot Arms. By identifying partners who not only provide superior products but also furnish comprehensive support and innovation, businesses can maximize the benefits of these transformative technologies in their operations.

The Impact of Digital Transformation on Collaborative Robotics in Manufacturing

The digital transformation in collaborative robotics is reshaping the manufacturing landscape, leading to enhanced productivity and safety. With the rise of collaborative robots (cobots), human operators now work alongside intelligent systems designed to adapt to their needs. This dynamic integration allows for Human-Centered Design methodologies, ensuring that safety remains a priority while maximizing efficiency on the assembly floor. The combination of human intuition and machine precision results in streamlined workflows and improved output rates, underscoring the pivotal role of cobots in modern manufacturing processes.

As industries move toward Industry 4.0 and embrace advanced digital technologies, the prospect of integrating cobots is becoming increasingly viable. This evolution is not only about automation but also emphasizes sustainability by optimizing resource usage and minimizing waste. With AI powering these collaborative robots, manufacturing is on the cusp of significant advancements, where cobots are equipped to learn and adapt to various tasks over time. These developments signify a shift towards more resilient and responsive manufacturing systems, paving the way for Industry 5.0, where human-robot collaboration will redefine operational capabilities.

Key Features of Next-Generation Collaborative Robot Arms

The rapid advancement in technology has propelled the capabilities of collaborative robot arms, redefining the manufacturing landscape. According to a recent report by the International Federation of Robotics, global sales of collaborative robots have surged by over 30% annually, signaling a shift towards automation that works alongside human workers rather than replacing them. These next-generation robot arms are designed with key features including enhanced safety, intuitive programming, and advanced sensing capabilities that significantly streamline production processes.

One of the standout features of these robots is their ability to learn and adapt in real-time. Utilizing artificial intelligence and machine learning, businesses can now implement robotic arms that optimize their performance based on the specific tasks they are given. A study published in the Journal of Robotics and Automation revealed that companies integrating collaborative robots into their operations reported a productivity increase of up to 25%. Additionally, the introduction of user-friendly interfaces has democratized access to robotic technology, allowing even small to medium enterprises to harness the power of automation effectively without requiring extensive technical expertise. This remarkable evolution in collaborative robotics is not just improving operational efficiency; it’s also setting the stage for safer and more flexible workplaces.

Enhancing User Experience through Advanced Programming Interfaces

The digital revolution is significantly enhancing user experience through advanced programming interfaces, particularly in the realm of collaborative robot arms. These interfaces allow operators to intuitively program and interact with robots, streamlining tasks and increasing productivity across various industries, including manufacturing and healthcare. Research indicates that companies adopting these advanced technologies can see efficiency gains of up to 30% in their workflows, transforming the way teams collaborate with robotic systems.

To maximize the potential of these collaborative robots, it's essential to understand the programming landscape. Here are a few tips: First, familiarize yourself with the most popular programming languages used in robotics, such as Python and JavaScript, as they often come with rich libraries that facilitate interaction with robot interfaces. Second, invest time in learning about the key frameworks that encapsulate robotic functionalities and integrate seamlessly with user applications. By doing so, you can design more effective user experiences and leverage the full capabilities of robotic arms.

Moreover, as industries continue to embrace automation, the demand for professionals skilled in advanced programming interfaces only increases. Keeping abreast of the latest trends and tools will empower users to create smarter, more efficient robotic systems that contribute significantly to the digital landscape.

Industry Statistics: Growth Projections for the Collaborative Robotics Market

The collaborative robotics market is experiencing remarkable growth, driven by the digital revolution that is reshaping how industries operate. Recent statistics indicate that the market for collaborative robots, or cobots, is projected to expand significantly over the next several years. Analysts forecast a compound annual growth rate (CAGR) of approximately 30%, with the market potentially reaching billions of dollars by 2025. This surge is attributed to the increasing demand for automation in various sectors, including manufacturing, healthcare, and logistics.

As companies seek to enhance productivity and efficiency, cobots are becoming essential tools. Unlike traditional industrial robots, cobots are designed to work alongside human operators, offering a unique blend of safety, versatility, and ease of use. This adaptability allows businesses to automate repetitive tasks while freeing human workers to focus on more complex, value-added activities. Furthermore, advancements in artificial intelligence and machine learning are leading to smarter cobots that can learn from their surroundings and improve their performance over time. The future of collaborative robotics promises not only to enhance operational capability but also to redefine the human-machine partnership across industries.

Digital Revolution Enhancing the Best Collaborative Robot Arm Experience - Industry Statistics

| Year |

Market Size (in Billion USD) |

Growth Rate (%) |

Key Applications |

| 2021 |

2.1 |

25.6 |

Manufacturing, Logistics |

| 2022 |

2.7 |

28.6 |

Assembly, Quality Control |

| 2023 |

3.4 |

22.2 |

Warehouse Automation, Medical |

| 2024 |

4.2 |

20.6 |

Food & Beverage, Electronics |

| 2025 |

5.2 |

19.0 |

Service Robots, Education |

Case Studies: Successful Implementations of Collaborative Robots in Various Sectors

In various sectors, the implementation of collaborative robots, or cobots, has transformed operational efficiency and productivity. One striking example can be found in the automotive industry, where manufacturers have successfully integrated cobots into their assembly lines. These robots work alongside human workers, assisting with repetitive tasks such as attaching components and quality checks. This collaboration not only reduces the physical strain on employees but also enhances precision in production processes, ultimately leading to higher output and reduced costs.

Another compelling case study emerges from the healthcare sector, where collaborative robots are revolutionizing surgical procedures. Hospitals have begun adopting cobots to aid surgeons, providing steady hands for intricate tasks such as suturing or assisting in minimally invasive surgeries. These robots are designed to understand human intent and react accordingly, leading to improved patient outcomes and increased surgical efficiency. The seamless integration of cobots into healthcare environments exemplifies the potential of technology to enhance human capabilities while maintaining a focus on patient care.

Digital Revolution: Enhancing the Best Collaborative Robot Arm Experience